Bunching

Single and double twist bunching machines are the two different machine types.

Single twist bunching machine

The advantage of the single twist bunching machine is a spinning of the take-up reel around its centre axis.

The production speeds to be achieved are in comparison to a drum twister much higher. The single twist buncher is limiting the bending radius of the ingoing individual products. In case the min. achievable bending radius of the single conductor is bigger than the bending radius inside the single twist machine another way of production has to be selected for example drum twister Thanks to modern control technology the single twist machines can perform good stranding results for the entire production length.

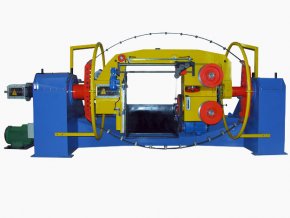

Double twist bunching machine

The double twist bunching machine is making two twists in turn of the bow. In the double twist bunching machine the take-up bobbin or reel is installed and a bow is rotating around the pay-off. The pay-offs for the individual products are outside of the machine. The machine usually has a housing. In addition to bobbins barrels can be used as pay-off for the individual wires. The individual elements are outside the machine housing and are going to the lay-plate in front of the machine. From the lay-plate they are going through the bow where the two twists are added before going onto the spool or drum.